Report Review

The following is a reveiw of an AI generated wood inspection report.

Help needed.

Hysterical Hysteresis

The Guild received a report for evaluation.

The report is so wrong, displaying a complete lack of knowledge of wood.

The inspector might have been right but without any measurements and misuse of the science, things are bad now to help the homeowner find a reasonable resolution.

This is longer than we normally would like to present to you but, this is too important for you not to read.

First, we found the report to be an AI generated wood inspection report.

We found the actual wordage the inspector copied, word for word.

The complaint is gaps that appeared shortly after installation. The installation was done in June 2024 in a remodeled home. (2100 sq. ft.) The wood was stored in an un-condition space, in a Mid-Atlantic state. The gaps appeared in late Fall.

The homeowner hired an “advanced inspector”, then a lawyer. The lawyer is an experienced construction litigator, who immediately had questions about the report.

Please remember, AI only gives back what is fed into it, and if the information is wrong, you got trouble when an inspector is not Educated Beyond Certification who uses AI to write reports.

A “true expert” writes their own reports.

These days we are hearing reports of AI generated reports being rejected by judges. I can’t testify to that, just what is being said in the ‘inspector grapevine’.

Report states:

“It appears” the 4 wide solid wood planks gained moisture before installation.”

There were no size measurements needed to confirm that evaluation.

The report had four moisture measurements with a capacitance moisture meter for 2000 sq. ft. MC reported in a 7% to 8% rangesd.

No gaps’ sizes were measured, no planks shrunken sizes measured. No span measurements.

The “appears” to have gain moisture before installation may be right, but without measurements, no proof.

Without data, there is no proof to support the statement.

A brief and to the point evaluation of the AI report was done by two wood scientists. Both responses were brief, B.S.

Interestingly, this was covered in our Fall Class in October (2025).

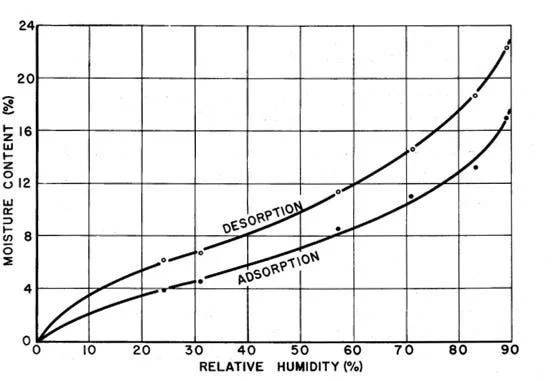

If you don’t believe us, well, one of the nation’s premiere wood scientists states in his book, used in Colleges and Universities classes, “For solid wood these differences (hysteresis) can be disregarded in practical calculations” – (Suchsland 2004)

The amount of shrinkage and swelling in the sorption “loops” is so insignificant that it can’t be measured with a sensitive caliber, and not appliable in practical calculations.

Look at the absorption and desorption loops in the graph above.

This is taken directly from the AI generated report.

“Hysteresis is the phenomenon where wood's moisture content (MC) is higher when it is losing moisture (desorption) than when it is gaining it at the same relative humidity (adsorption).”

“For wood floors, this means that after a dry season, they will swell less when humidity returns to its previous level than they did when humidity first dropped. This causes seasonal expansion and contraction and affects how much a floor's dimensions change, impacting factors like gaps and potential buckling.”

Remember, the amount of change in size is so insignificant that Sushsland wrote in his book, based upon research, should not be used in calculations.

Most people start to see 1/64” to 1/32”. A caliber can easily measured 1/64”. How did we get from this to gaps.

Wait, it gets worse:

“How hysteresis affects wood floors:

Seasonal changes: Wood floors naturally expand and contract with seasonal humidity changes. Hysteresis means the amount of movement in a full annual cycle is more complex than a simple back-and-forth.

Moisture history matters: The amount of moisture a piece of wood holds at a certain relative humidity depends on whether it's getting wetter or drier at that moment, as well as its entire past history.

More swelling than shrinking: A floor will require a higher relative humidity to achieve its maximum size than the lowest relative humidity it experienced during a dry period. f

·Impact on installation: This is a crucial factor in designing and installing floors. For example, installers need to account for a floor's total potential movement to prevent gaps from appearing or the floor from buckling.

At this point, the inspector inserted more fluff, we think, to show how much he thought he knew, but didn’t. The fluff is at the bottom of this evaluation.

When you start to see “fluff”, the inspector is trying to hide his ignorance.

Once again from our recent class in October: “EMC in the initial desorption (from the original green condition of the tree) is always greater than in any subsequent desorptions” – Wood Handbook

“For solid wood these differences (hysteresis) can be disregarded in practical calculations” – (Suchsland 2004)

What have we learned?

Depending upon AI to write reports can lead to inaccurate reporting, and deceit.

Education is still the best tool for scientific examinations and reporting.

Whomever taught this, is ignorant of practical wood science. This is too important to be taught by uneducated people.

You should only hire Guild Educated Inspectors and Examiners for your clients.

Fluff, that can be from any wood mill’s installation instructions, trying to cover ignorance.

Engineered vs. solid wood:

Solid wood floors are more susceptible to movement caused by hysteresis than engineered wood floors, which are designed to be more stable.”

“What you can do?

·Acclimate the flooring: Ensure the wood is brought to your home and allowed to acclimate for several days to match the average temperature and humidity levels of your home before installation, as recommended by the National Wood Flooring Association.

Control humidity: Use humidifiers in the winter and dehumidifiers or air conditioning in the summer to maintain a consistent humidity level, ideally between 35% and 55%.

Monitor levels: Use a hygrometer to monitor your home's humidity levels and make adjustments as needed.

·Allow for expansion: Ensure installers have left the correct expansion gaps around the perimeter of the room to allow the wood to move safely without buckling”.